ELECTROSTATIC PRECIPITATORS

The electrostatic precipitator with its countless possible applications is to date the most economical method for the dedusting of gases. Firstly, it requires little energy compared to other systems and secondly, the maintenance and spare parts costs are very low. In addition, the lifespan of an electrostatic precipitator usually exceeds the upstream production equipment such as furnaces, boilers and mills.

Discharge electrodes that are fed with rectified negative high voltage emit electrons. These reach to the collecting electrodes and encounter dust particles on their way, which are thereby negatively charged and transported to the earthed collecting electrodes under the influence of the electric field. There they adhere. Mechanical rappers periodically clean the collecting and discharge electrodes. The main features of the ELEX electrostatic precipitators are the unbreakable RS electrodes and the maintenance-friendly design.

UMBAUTEN /

UPGRADES

Durch den Umbau von bestehenden Anlagen können mit relativ geringem Aufwand Kapazitätserhöhungen bewältigt oder neue Grenzwerte eingehalten werden. Umbauten erfordern ein hohes Mass an Erfahrung, da teilweise während des laufenden Betriebes und/oder in beengten Platzverhältnissen gearbeitet werden muss. Eine lange Liste von Referenzen ist der Beweis für die hohe Qualität unserer Umbaukonzepte. Dabei ist es uns wichtig, nur alles wirklich Notwendige zu ersetzen und bestehende Komponenten bestmöglich weiter zu verwenden.

Mögliche Varianten sind:

– Anbau von zusätzlichen Feldern

– Umrüstung von Fremdfiltern auf ELEX-Standard

– Erweiterung der Niederschlagsfläche durch Verlängerung der Feldlänge

– Einsatz alternativer HS-Technologien (SMPS oder Dreiphasen-Aggregate)

– Umrüstung von Elektrofiltern auf Hybridfilter

– Umrüstung von Elektrofiltern auf Gewebefilter

SCOPE OF APPLICATION

ELEX offers you a solution for every application, than electrostatic precipitators can be built in countless variants. We supply dry and wet electrostatic precipitators, in horizontal or vertical design, in accordance with your specifications and requirements. We develop the technically optimal and most economical solution for every application. Continuous optimisation and further development, integrating the latest technologies, as well as the evaluation of measurements under many different operating conditions, have yielded an immeasurable wealth of experience. With ELEX, you choose a system that incorporates unrivalled know-how.

Zur Stärkung der Aktivitäten im Bereich Umwelttechnik für Stahlwerke hat die ELEX AG zusammen mit der SMS Siemag AG 2008 das neue Unternehmen SMS ELEX AG (http://www.sms-elex.com/) mit Sitz in Schwerzenbach gegründet. Die SMS ELEX AG baut und vertreibt Trocken- und Nass-Rundelektrofilter einer neuen Generation für Stahlwerke.

SUCCESS FIGURES

We have not only constructed countless electrostatic precipitators - we have also done this in a wide spectrum of sizes. No project is too big for us! We will gladly convince you not only with words, but also prove our expertise and know-how with facts and figures.

7321

Electrostatic precipitators

43'680

2'800'000

REFERENCES

Thanks to decades of experience and countless measurements carried out, ELEX has a huge wealth of experience. Below we have listed a small excerpt from our references. For further reference information or if you are interested in a plant visit, please contact us.

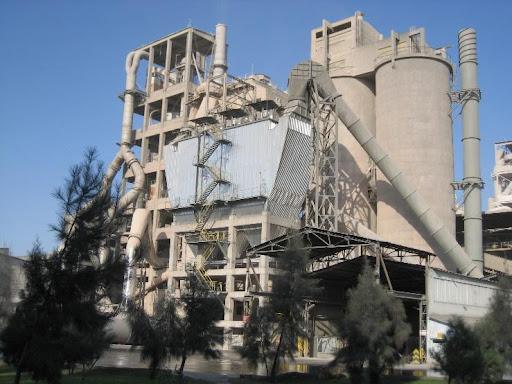

Installation: Adana (Turkey); Electrostatic precipitator after preheater kiln / Raw meal mill

Fukushima (Japan), Electrostatic precipitator for multiple hearth furnace for CaCO 3

Müll- und Schlammverbrennungsöfen

Thanks to decades of experience and countless measurements carried out, ELEX has a huge wealth of experience. Below we have listed a small excerpt from our references.

Für weitere Referenzauskünfte oder bei Interesse für einen Anlagenbesuch nehmen Sie bitte Kontakt mit uns auf.

Would you like more references?

Please enter your e-mail address:

SERVICE

ELEX gas cleaning systems are characterized by a very high availability and low maintenance costs. However, if a malfunction occurs, rapid assistance is essential. In case of emergency, we are there for you and provide you with competent and reliable support on site.