SERVICES

ELEX Gasreinigungsanlagen zeichnen sich durch eine sehr hohe Verfügbarkeit und einen geringen Unterhaltsaufwand aus. Für die Funktions- und Werterhaltung der Anlagen empfehlen wir dennoch Revisionen durchzuführen. Sollte während des Betriebs ein Störfall eintreten, ist rasche Hilfe unersetzbar. Wir sind im Ernstfall für Sie da und unterstützen Sie vor Ort; kompetent und zuverlässig.

Aufgrund der durch das Coronavirus stark eingeschränkten Reisemöglichkeiten können wir momentan nur die wenigsten unserer Kunden persönlich vor Ort betreuen.

Kommt es trotzdem zu einer Anlagenstörung, setzen wir unsere ganze Kreativität ein, um das Problem aus der Ferne zu lösen. Dank dem Einsatz von zeitgemässen Hilfsmitteln – wie TeamViewer Pilot – sind wir in der Lage, durch die Smartphone-Kamera Ihres Technikers vor Ort das Problem zu erfassen. Wir können sämtliches Equipment genau unter die Lupe nehmen und den Techniker zur Problemlösung führen.

Noch nicht überzeugt? Weitere Informationen über den Einsatz von TeamViewer Pilot finden Sie hier.

SERVICES

Spare parts

Our products meet the highest quality standards. Nevertheless, over time it may become necessary to replace certain components. You will receive the best possible support from our spare parts department so that you have the optimum selection of spare parts on site. To ensure good availability, we also have a wide range of stock parts.

Inspektion & Revision

The plants we install should be inspected once a year to ensure the longevity of the systems. The inspection only takes approximately one day per installation, as our inspection team works with extreme efficiency due to many years of experience. The inspection also significantly increases the availability of the installation. This is normally done in the course of a complete overhaul of the upstream production facilities. An overhaul takes place after one to three years, depending on the industry. If spare parts are required, the need can be recognized at an early stage and planned accordingly.

Retrofit & Upgrade

By reconstructing existing installations, our customers can cope with capacity increases or comply with new limit values at relatively low cost. Conversions require a high degree of experience, as work sometimes has to be carried out during ongoing operation and in confined spaces. A long list of references is proof of ELEX's reconstruction competencies. We focus on replacing only the necessary parts and on using existing components in the most optimum way.

Commissioning

Once the installation has been completed, our commissioning engineers check the entire installation. All sensors and actuators get tested regarding their function, the signals to our PLC and to the central control room are checked and the step chains are closely inspected. Afterwards you will get a full instruction of the new plant from us and you will be made aware of all maintenance tasks. Our experienced commissioning engineers are also available to support you during the start-up of the installation, to ensure that the roadmap you have drawn up is adhered to exactly.

Troubleshooting

The high level of flexibility of our employees makes it possible to send a troubleshooting team to the site and provide assistance within a very short time in case a customer has a problem. This is because ELEX's employees know the business and are aware that installation shutdowns are not always planned and that rapid action is sometimes indispensable. Thanks to the expert knowledge of our employees, an impending plant shutdown, reduced operation or other consequences may even be prevented. Contact us - the service team is looking forward to solve your problems.

Remote Maintenance

Using remote maintenance, the ELEX’s service team can directly solve customer’s problems and rapidly take action. This is possible due to the fact that ELEX can access the necessary data, which is located at the customer's premises, in order to make an initial assessment. The reason for this is that the remote maintenance solution complies with the latest IT standards which enables a special form of cooperation. Of course, data privacy has the highest priority and we attach great importance to the highest security standards. In order to meet the security guidelines of all customers, we can also individually adapt the remote maintenance system to the customer's needs.

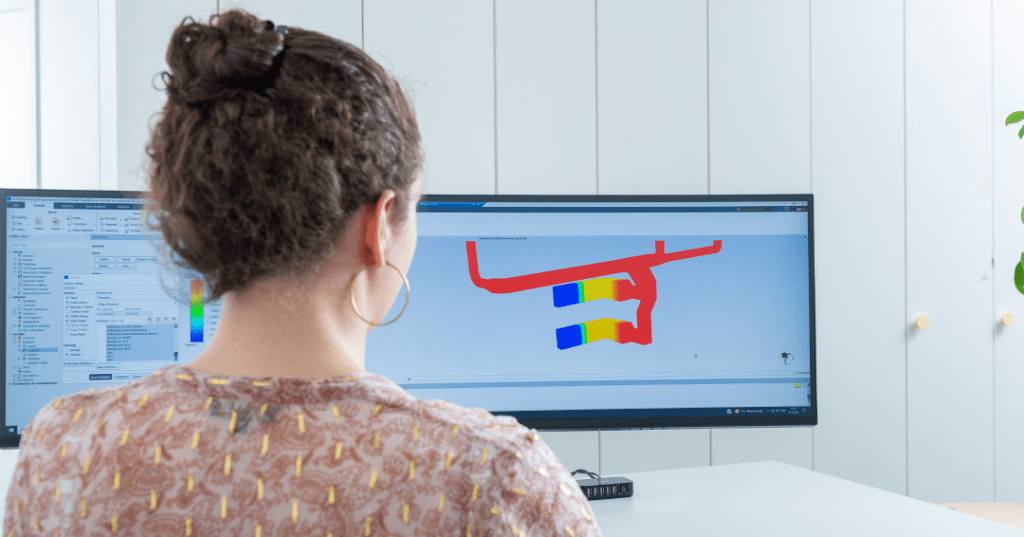

CFD

Balanced gas distribution is one of the most important points for efficient operation. In this context, computational fluid dynamics is an established method for solving problems in fluid mechanics. By using CFD simulation, we can optimize existing or new installations for you. Because of our long experience and modern simulations, we know what is important. From an electrostatic precipitator to complete gas duct systems, we can simulate anything for you.

Consulting / Expertise

No matter where the shoe pinches you, our engineers can help you across the entire spectrum of flue gas cleaning. With over 7000 installed plants, we are your contact when it comes to cleaning industrial waste gases. An expertise carried out by our specialists will quickly provide you with exact answers to your questions. We will then be pleased to advise you on how to solve the problem. Due to our decades of experience, we solve your problem quickly and competently.

Project Measurement

Are you interested in increasing your performance, but don't know exactly what your existing installation is capable of? We can gladly send an engineer to your site for a project measurement and subsequent analysis. After that, you will have a clear overview on what is possible with the current installation. The clarification of the current status allows us to determine what can be optimized and realigned in a next step.

Assembly

Through our experienced site supervisors, we are able to carry out assignments all over the world. Whether it is in the form of a cooperation delivery or a turnkey order. Our site supervisors know the structure of our installations and, due to their many years of experience, always maintain the overview on the construction site. Their knowledge of the construction site organization and installation procedures guarantees an efficient and competent installation of the plants. Our installation team has already mastered many challenges concerning the construction of installations and is looking forward to the next one.

Dust Resistivity Measurements

In our in-house laboratory, we can determine the specific resistivity of dust. With many years of experience in this field and countless measurements, we are able to identify the right electrostatic precipitator for all applications. By measuring the resistivity, we can specify the optimal operating temperature and thereby increase the efficiency of the electrostatic precipitator, which promotes improved operation of your electrostatic precipitator.

Catalyst Management

As part of catalyst management, we monitor our customer's catalyst modules, draw sample elements during revisions and analyze them in our laboratory for our customers. The analyses enable us to draw conclusions about our customer's operation and optimize the service life of the catalyst, which has a cost-reducing effect for our customers. Therefore, our customers are always up to date and know how much performance their SCR plant has and when it is time to replace the catalyst modules.